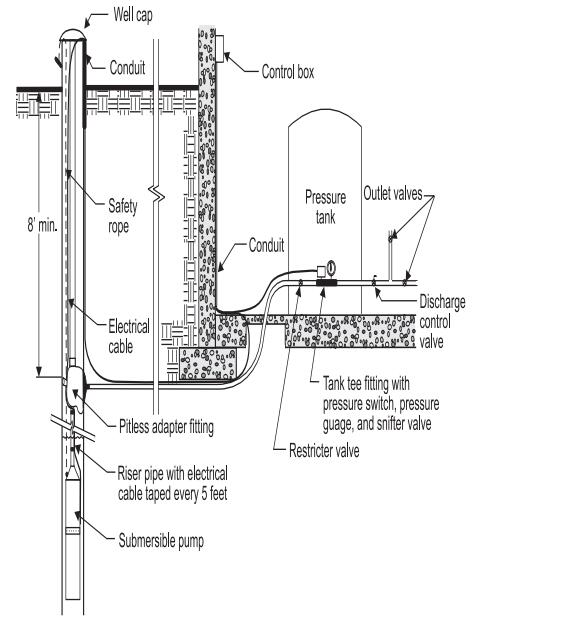

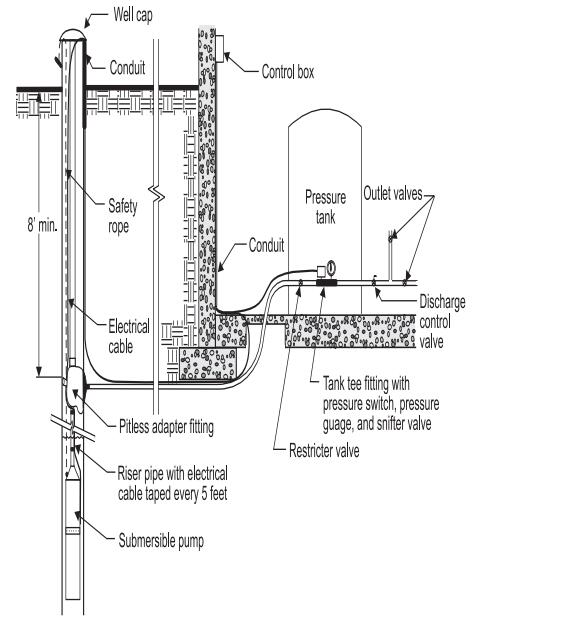

A typical installation for a submersible pump, pressure tank and fittings is shown in Figure 3. Prior to well installation, the pump should be wired, submerged in a container of water and operated.

The size and type of drop pipe used for a submersible installation depends on the following:

1. Depth to the water and pumping level.

2. Pressure that the pump can develop.

3. Allowable friction loss in the drop pipe.

4. Weight of the pump.

When making male adaptor connections for the drop pipe, use only nylon (with three serrations), bronze or galvanized (with seven serrations). The pipe should be warmed with hot water (less than 65°C) before making a connection. Never use a torch to heat plastic pipe as it can crystallize the polyethylene. All connections must be double clamped with 100 per cent stainless steel clamps, and the screw heads should face opposite directions.

A nylon safety rope is recommended, and it should be tied using a bowline knot. After installation, the rope should be tightened and tied at the top of the well casing to reduce the free fall distance in case of a pitless unit or pipe failure. The electrical cable to the pump can be inserted into a 3/4 inch plastic pipe to protect it from rubbing against the side of the well casing.

Submersible pumps should be protected from power surges or lightning strikes. Pumps with 1 horsepower motors or less often have built-in protection, but this condition should be verified with the supplier and manufacturer’s specifications. Alternatively, a lightning arrestor may be required to protect the pump. The arrestor should be wired to the line conductor and back to the electrical grounding system with not less than No. 6 AWG copper wire or cable. In some power supply situations, the electrical grounding system is connected to a steel well casing. Electrical grounding details should be confirmed by your electrical contractor or an electrical inspector if you are doing your own wiring.